By Jason Feulner, Finger Lakes Correspndent

(Note: this story is part two of a two-part series highlighting some unique production choices at Shaw Vineyard.)

Shaw Vineyard just released its 2005 reds this month.

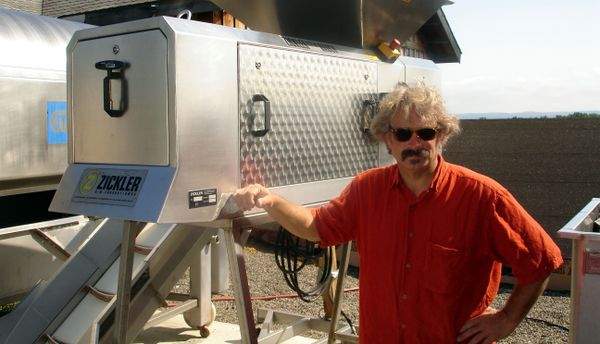

In the Finger Lakes, that fact would normally be the story in and of itself, but the true story starts in 2004 when Steve Shaw called the Europress California office to order a specialty-built Rauch A-8 Crusher/De-stemmer.

"I tried a French de-stemmer that had some very limited variable options," winemaker and owner Steve Shaw remembers. “It just didn’t work well as I wanted. I called Europress to get them to custom-build a variable speed version of their common de-stemmer. It cost me 20% more to get the results I wanted."

"They really thought I was crazy when I told them I wanted no crusher at all on the de-stemmer. Between the variable speed and the complete lack of crusher, it’s a unique machine."

The device, which Steve says was the only Europress had made at the time of its creation, is a de-stemmer that has a nearly infinite number of speeds available to the winemaker. All red varieties are conveyor-fed and de-stemmed at the lowest possible impact point, the berries being released fully intact into vats for cold soaks, eventually resulting in whole berry fermentation after inoculation with sulfur. The desired yeast is added to the must, but no artificial heat is used.

"Everything is done by hand." Steve emphasizes. "There are no pump-overs with a hose pump for any grapes, clusters or must — only later with fermented juice. Punch downs are done by hand. We lift what berries are left after fermentation into the press with a conveyer, and we press at a very, very low 1 bar of pressure, Champagne style."

Steve’s philosophy on handling grapes stems from his background both observing and engaging in winemaking. A 30-year-grower, he witnessed firsthand how different Finger Lakes wineries treated his grapes and what kind of wines resulted. Steve cut his winemaking teeth at Silver Thread in the late 1990s, and then began to plan his own venture in 2000.

To further his education, he took trips to Champagne, Burgundy, Bordeaux, and Napa and spoke to whomever he could about winemaking techniques.

"I noticed, especially in Bordeaux, that there was a lot of talk about handling of cooler climate grapes and how it affects the flavors. I compared that to what I had learned in the Finger Lakes in the cool climate here.”

Steve built his production facility in 2002, an energy-efficient building that he does not even have to heat most winters. He left room in anticipation of other winemakers wanting to rent space the facility and, much to Steve’s delight, Morten Hallgren soon arrived to produce wines for his new winery, Ravines Wine Cellars.

“I tell people it’s like taking batting practice with Derek Jeter,” Steve jokes. “Morten is a master winemaker with a great deal of experience, and he has been an amazing consultant as I’ve pursued my own style of winemaking. Our views on grape handling are very similar and it’s been a beneficial relationship.”

Beyond the unique machinery and delicate handling, Steve is adamant that his reds must take time to age before they are released. “It’s a luxury I give myself, but it’s important to me to give the reds time to develop. It’s a common practice in other winemaking regions.”

I found that the just-released Shaw 2005 reds, a merlot, cabernet franc, and cabernet sauvignon, are all prime examples of the vintage, with nice balance, ripe fruit, and expressive aromatics. The cabernet sauvignon will surprise many tasters who have not seen many quality bottlings of that varietal in the Finger Lakes; much like his 2003 version, Steve Shaw’s 2005 cabernet sauvignon is a tasty, enjoyable red.

Steve Shaw is proud of his wines, but he is also proud of the environmentally-friendly facility that has evolved under his watch. “The tank building rarely needs to be heated. I put the underground barrel cellar directly beneath the tasting room, and the heat it gives off keeps this place warm in the winter. Between the design of these buildings and the way I handle my grapes, I think this is a pretty distinctive operation for the Finger Lakes. The whole idea at Shaw is gentle extraction from the grapes of the desired flavor components that the particular growing season offers.”